VAD 4200A Proportional Asphalt Distributor

The VAD4200A Proportional Asphalt Distributor differs from the VAD5400A model in terms of its total spreading width of 4200mm and pneumatic spray bar movement. The operator inputs the amount of material to be spread on the control panel, and the system utilizes data from the radar, asphalt pump, and spray bar to adjust the optimal pump flow rate. Similar to the VAD5400, the VAD4200A can instantly display all values and provide detailed statistics on the spreading process.

Features

| Capacity | 8.000 – 13.500 Liters |

|---|---|

| Isolating Sheet | Aluminium Sheet 1mm |

| Isolating Material | Rockwool 50mm |

| Power | Vehicle PTU (Power Transmission Unit) |

| VAD 3600A / Controls | Hydrostatic, Digital Control |

| VAD 3600M / Controls | Manual Control from Cabin |

| Pump Type | 3”VA Pump (70m3/h) |

| Spray Bar Span | 2400 – 4200mm |

| Spreading Lane Width | 450mm, 12 Groups of Pneumatics |

| Spray Bar Drive | Pneumatic – Electric On-Off |

| Valve Controls | Pneumatic – Electric |

| Heating System | Two Diesel Burners(min 190kw, max 310kw) |

| Drive Type | Hydrostatic Control |

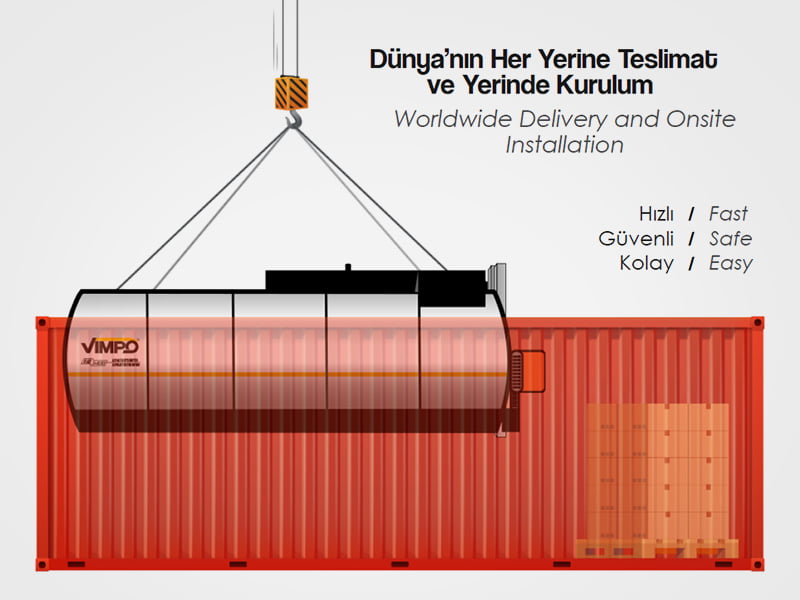

Logistics

When it comes to asphalt distribution, the VAD Series Asphalt Distributors are tailored to meet our customers’ specific requirements, ensuring suitability for diverse locations worldwide. Thanks to our partnership with MSB Group, logistics for both new and used trucks are efficiently managed, resulting in significant savings on truck import costs. The innovative design of the VAD Series allows for pre-assembly into a standard 40ft container, further reducing transportation expenses. Installation and training can be completed swiftly, typically taking only 5-7 days. Choose the VAD Series for cost-effective and timely asphalt distribution solutions.

Asphalt Pump

Discover the innovative design of TC Construction’s Asphalt Pump, seamlessly integrated for optimal functionality. Mounted on a welded plate affixed to the tank’s backplate, this pump boasts two intake lines and two discharge lines, ensuring efficient asphalt handling.

The asphalt pump’s body is intelligently crafted to remain within the tank, preventing freezing and ensuring reliability in all conditions. Internal valves on the pump eliminate the need for intricate piping systems, streamlining operations and enhancing overall system performance.

Experience a new level of maintenance and cleaning efficiency, as TC Construction prioritizes user convenience. Swift and easy access allows for prompt upkeep, keeping downtime to a minimum. Choose TC Construction for a reliable, user-friendly Asphalt Pump that delivers top-notch performance without compromising on ease of maintenance.

Safe & Fast Heating

Prioritize safety and efficiency with our cutting-edge heating solution. The 8’’ diameter design incorporates two flame tubes arranged in a U format along the tank, ensuring uniform and rapid heating. Equipped with two units of 26kg/h, with a power range from a minimum of 190kw to a maximum of 310kw, our electric burner guarantees quick and efficient material heating.

Take command with user-friendly controls conveniently located on the rear control panel. With a simple press of a button, operators can enter the desired temperature value on the screen and activate the heating process. Safety is paramount – once the material reaches the specified temperature, the burners automatically switch off, providing peace of mind and preventing any potential risks associated with overheating. Trust in our heating system for a perfect blend of speed, efficiency, and safety in your operations.

Control Panel Excellence:

Experience unparalleled control at your fingertips with our specially designed control panel, strategically placed in the operator’s cab. This intuitive interface provides the operator with seamless access to a myriad of functions, ensuring a comprehensive and efficient operation.

Navigate effortlessly through features such as circulation, automatic/manual spreading, intermediate pump control, and system cleaning. Take charge with precision controls for pneumatic spray-bar locks, positions, paving width, and spray bar movement, all conveniently centralized on the control panel.

Empower your operators with a user-friendly interface that enhances their ability to manage and optimize various aspects of the operation. Trust in our state-of-the-art control panel to streamline your workflow and elevate the efficiency of your equipment.

Pump Function Excellence:

Unlock precision and control with our dedicated Asphalt Distributor Pump, designed to execute critical functions seamlessly. This high-performance pump incorporates valves strategically positioned inside the pump and along the piping, offering unparalleled reliability and efficiency. Operators can take command directly from the cabin through the control of pneumatic actuators.

Key functions include:

- Re-Suction: Effortlessly manage re-suction processes for optimal distribution.

- Tank Filling and Tank Circulation: Streamline tank filling and circulation operations with precision.

- Automatic/Manual Spraying: Choose between automatic and manual spraying modes for flexibility in application.

- Tank Discharge: Ensure efficient and controlled tank discharge with ease.

- Intermediate Pump: Optimize performance with the intermediate pump feature for enhanced versatility.

- System Cleaning: Maintain equipment hygiene with straightforward system cleaning controls.

Empower your operations with a pump designed to handle these critical functions with precision and reliability. Providing operators with the control they need for a seamless workflow.

Fully Automatic Spreading:

Explore the cutting-edge technology of TC-Construction, specifically tailored for the VAD5400 and VAD3600A models. With precision flow adjustment and a specially designed 5400mm spray-bar, achieve impeccable spreading performance. This advanced system operates by seamlessly interpreting data such as vehicle speed and spread width, instantly adjusting pump flow to achieve the desired spreading amount.

Experience unparalleled control as the spreading width can be effortlessly increased or decreased during operation. Empowering operators to adapt to varying road conditions. The system synchronizes with the operator’s speed adjustments, ensuring a seamless spreading process. Whether accelerating or slowing down, the VIMPO system efficiently initiates, maintains, and completes spreading tasks. It’s allowing operators to focus on driving with confidence. Elevate your construction experience with TC-Construction’s intelligent and user-friendly features.

Solid Mechanical Joints:

Elevate your asphalt distribution experience with our Solid Mechanical Joints, designed for superior sealing and prolonged operational life of the spray bar. The connectors featured in the VAD Series Asphalt Distributor are engineered to enable versatile movement. Allowing the entire 5400mm spray-bar to be effortlessly raised, lowered, or shifted sideways.

Key Features:

- Teflon and Copper Threaded Sealing: Ensure reliable sealing with advanced materials such as Teflon and Copper threads, providing durability and longevity in operation.

- Flange Structure for Easy Maintenance: The incorporated flange structure simplifies maintenance and repair processes, streamlining any necessary adjustments or fixes.

Experience a robust and efficient asphalt distribution system that prioritizes durability. Ease of maintenance, and precise control over the spray bar, enhancing overall performance and extending the lifespan of your equipment.

Road construction machinery, Hot mix plant, Asphalt paver, Asphalt distributor, Road roller, Motor grader, Asphalt mixing plant, Cold milling machine, Soil stabilizer, Concrete mixer, Pothole patcher, Dump truck, Bulldozer, Asphalt recycler, Chip spreader, Trencher, Road marking machine, Vibratory plate compactor, Concrete batch plant, Crack sealing machine, Street sweeper, Pavement saw, Gravel spreader, Concrete slipform paver, Milling machine, Bridge inspection vehicle, Road cutter, Concrete pump, Guardrail installer, Sand spreader

Check out other Machinery