What exactly is a Crack Filling Machine used for?

Over time, small cracks may form in asphalt surfaces due to environmental factors like rain and snow, which can lead to more serious damage if left untreated. These cracks often occur at pavement joints and along the edges of roads.

By utilizing the Vimpo Crack Filling Machine, these cracks can be filled with mastic asphalt to extend the lifespan of the road and minimize the need for costly maintenance.

Features

| Capacity | 400 Liters |

|---|---|

| Insulation Cover | Aluminium Sheet 1mm |

| Insulation Material | 50mm Rockwool |

| Power | 22 kW Diesel Engine |

| Drive Type | Hydrostatic |

| Pump Type | Vimpo VF-35 Helical Gear Pump |

| Valve Actuators | Pneumatic |

| Heating System | Digitally Controlled Diesel Burner |

| Burner Properties | Diesel Burner(min. 60.2 kW – max. 118 kW) |

| Axle Type | Double Torsion Axle |

| Axle Load | 3.500 Kg |

Logistics

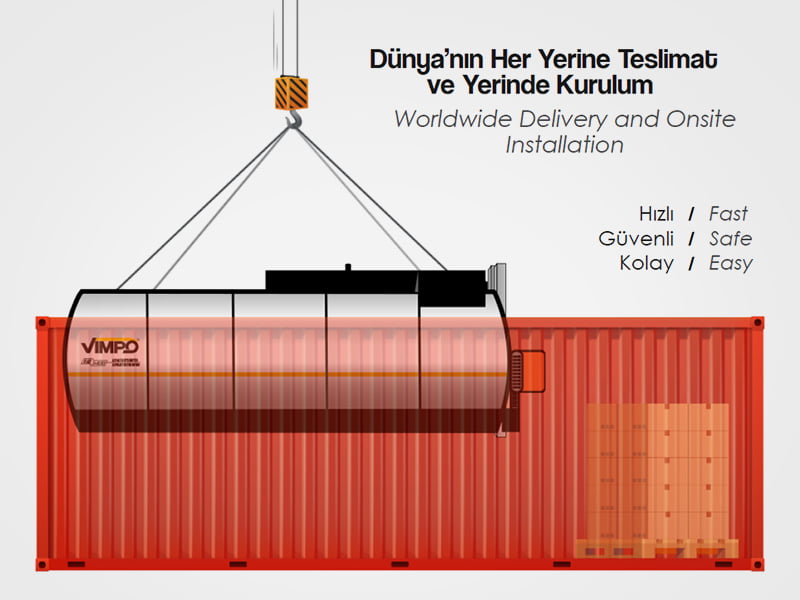

When it comes to asphalt distribution, the VAD Series Asphalt Distributors are tailored to meet our customers’ specific requirements, ensuring suitability for diverse locations worldwide. Thanks to our partnership with MSB Group, logistics for both new and used trucks are efficiently managed, resulting in significant savings on truck import costs. The innovative design of the VAD Series allows for pre-assembly into a standard 40ft container, further reducing transportation expenses. Installation and training can be completed swiftly, typically taking only 5-7 days. Choose the VAD Series for cost-effective and timely asphalt distribution solutions.

Crack Filling Machine Explanation

After a period of time, tiny cracks develop in the asphalt or at the intersections of pavement edges and road surfaces on newly constructed roads. When rain or snow water seeps beneath the road and freezes during cold weather, it can lead to deformities.

To prevent such deformities, Vimpo Crack Filler is applied to fill these cracks on roads. The VCF400 Crack Filling Machine is used to fill joints and cracks in asphalt surfaces with a special mastic asphalt.

The VCF400 Crack Filling Machine, used on asphalt surfaces, can be effectively utilized on highways, bridges, viaducts, city roads, and airports. Possessing an O2 Type Approval Certificate, this machine not only fills cracks but also helps in reducing maintenance costs by preventing any potential larger damages.

Safety

The VCF400 Crack Filling Machine ensures safe and efficient operation, with its user-friendly design. It features a diesel engine and hydraulic system, making it more durable and resistant to long hours of work and tough conditions. This road maintenance and repair machine, driven by a diesel engine with a 400-liter tank capacity, is designed in a trailed type.

In conclusion, the VCF400 Crack Filling Machine is a versatile and efficient equipment that can be used in various areas such as highways, airports, city streets, and neighborhoods.

Off Grid

With its diesel engine drive and hydraulic equipment, it can operate without the need for an external power source. The hot oil heating system ensures safe and precise control of temperature for optimal performance. The electronic control of mixing, circulation, heating, and filling allows for more efficient operation. The electrically heated filling gun and installation ensure continuous and high-quality filling, with precise control provided by the electronic trigger.

Road construction machinery, Hot mix plant, Asphalt paver, Asphalt distributor, Road roller, Motor grader, Asphalt mixing plant, Cold milling machine, Soil stabilizer, Concrete mixer, Pothole patcher, Dump truck, Bulldozer, Asphalt recycler, Chip spreader, Trencher, Road marking machine, Vibratory plate compactor, Concrete batch plant, Crack sealing machine, Street sweeper, Pavement saw, Gravel spreader, Concrete slipform paver, Milling machine, Bridge inspection vehicle, Road cutter, Concrete pump, Guardrail installer, Sand spreader

Check out other Machinery